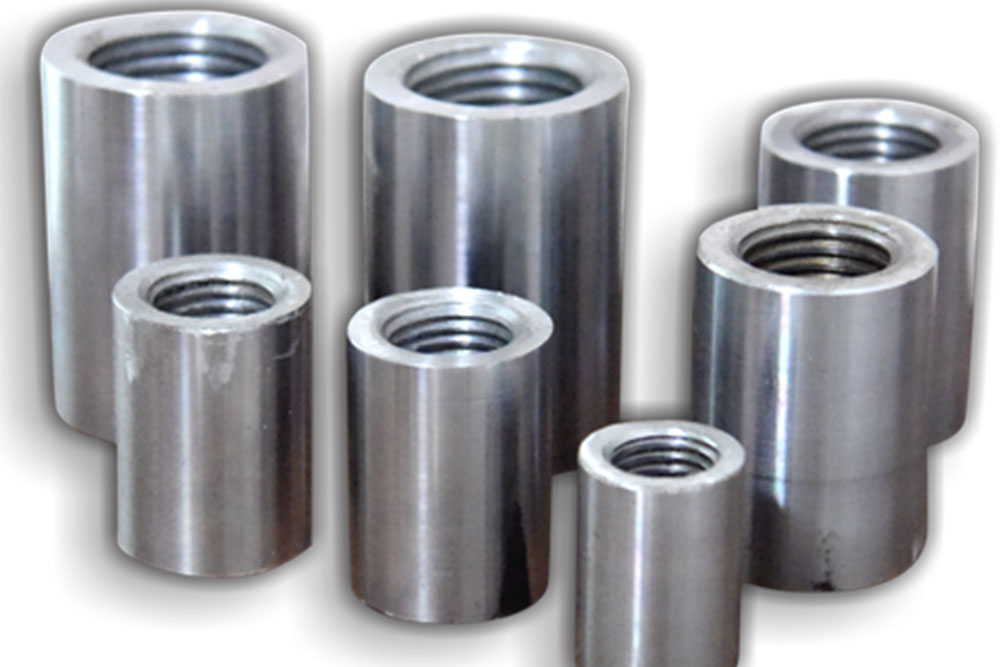

REASON TO PURCHASE REBAR COUPLERS FROM KAMAR

-

Using KAMAR Rebar Splicing offers various advantages over the method of overlapping of reinforcement bars. Some of the prime reasons are as follows.

- Splice rebar performs like continuous reinforcement due to mechanical joint,unlike lapping which has complete dependency on concrete.

- Steel wastage is reduced significantly ,save lap length steel.

- Steel congestion is reduced due to elimination of laps .This also aides in proper flow of concrete in the critical zones and hence improves the quality of the overall structure .

- Using couplers provides superior cyclic performance as compared to lap joint it also allows greater flexibility for the designer.

- It is possible to easily verify joint strength in case of coupler as compared to lap splice where testing is cumbersome and not regulated.

- For the contractor usage of coupler reduces labour cost for installation and handling of steel. The construction schedule is improved and there is saving on valuable crane time on project.

- In last steel wastage and lap is reduced that is definitely save MONEY AND PRECIOUS TIME.